Key Features

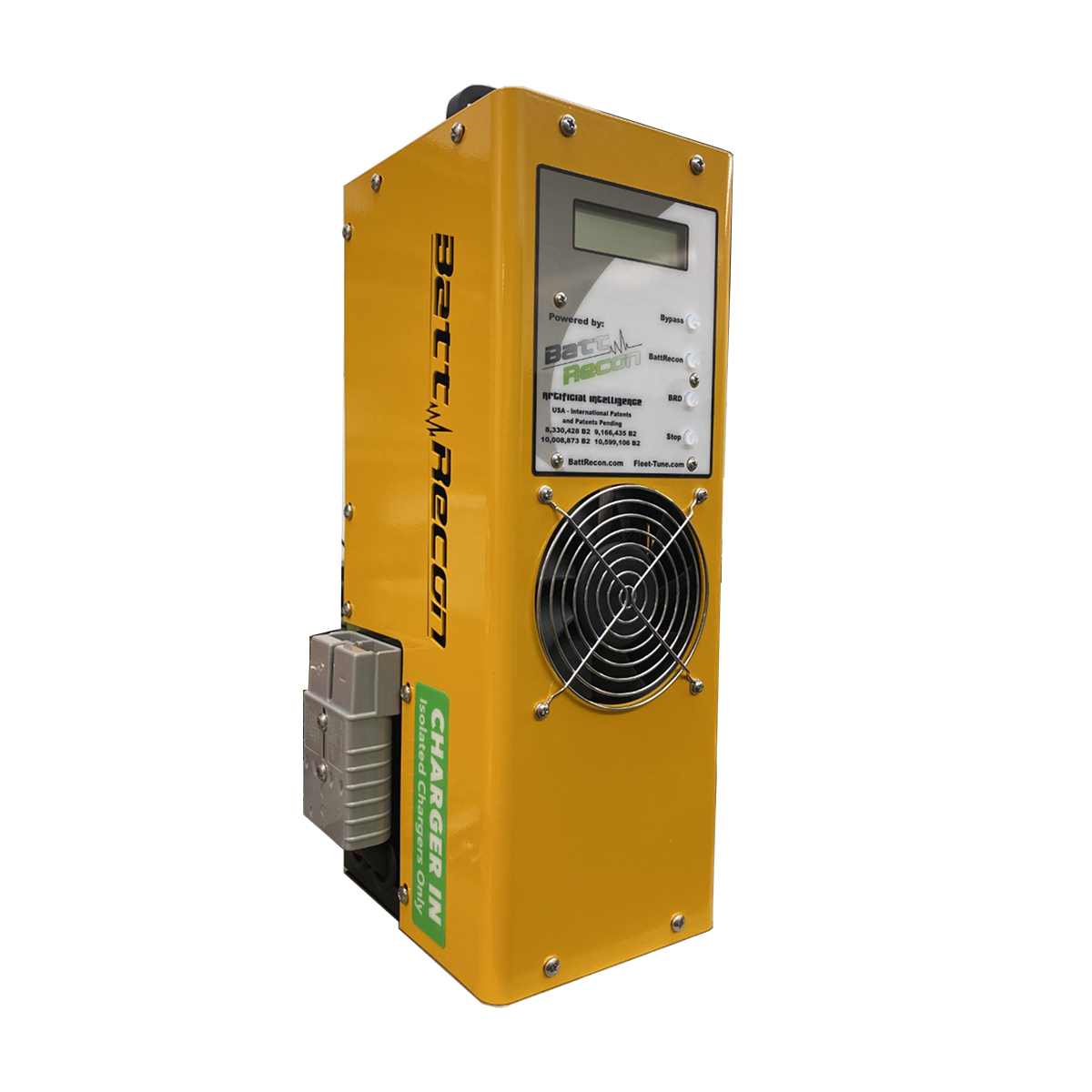

With features such as portability, low cost, no operator training or experience requirements, and the capacity to service large fleets of batteries at one time, the Model 8000 is a tremendous business opportunity for service-related companies.

| 80mv: 24, 36, and 48 vdc / 8012: 12vdc |

| Use at the client’s facility: No battery transportation |

| Battery self-powered |

| No training needed |

| Fully automated plug ‘n play |

| No service interruption – operates in the background during normal battery recharging |

| Service or optimization mode |

| Artificial Intelligence-based self learning for each individual battery |

| May be permanently wired into a vehicle or base station, to automatically and periodically desulfate batteries |

| WiFi capable |

| Multiple US and international patents issued and pending |

Why Choose the 8000?

During the previous 100 years of lead-acid battery operation, battery maintenance has been limited to charging and overcharging in an attempt to desulfate the battery, then performing external corrosion treatments and watering. There has never been a quick, effective way to desulfate a battery and restore lost performance without transportation to and from a dedicated, facility-based battery shop.

During the previous 100 years of lead-acid battery operation, battery maintenance has been limited to charging and overcharging in an attempt to desulfate the battery, then performing external corrosion treatments and watering. There has never been a quick, effective way to desulfate a battery and restore lost performance without transportation to and from a dedicated, facility-based battery shop.

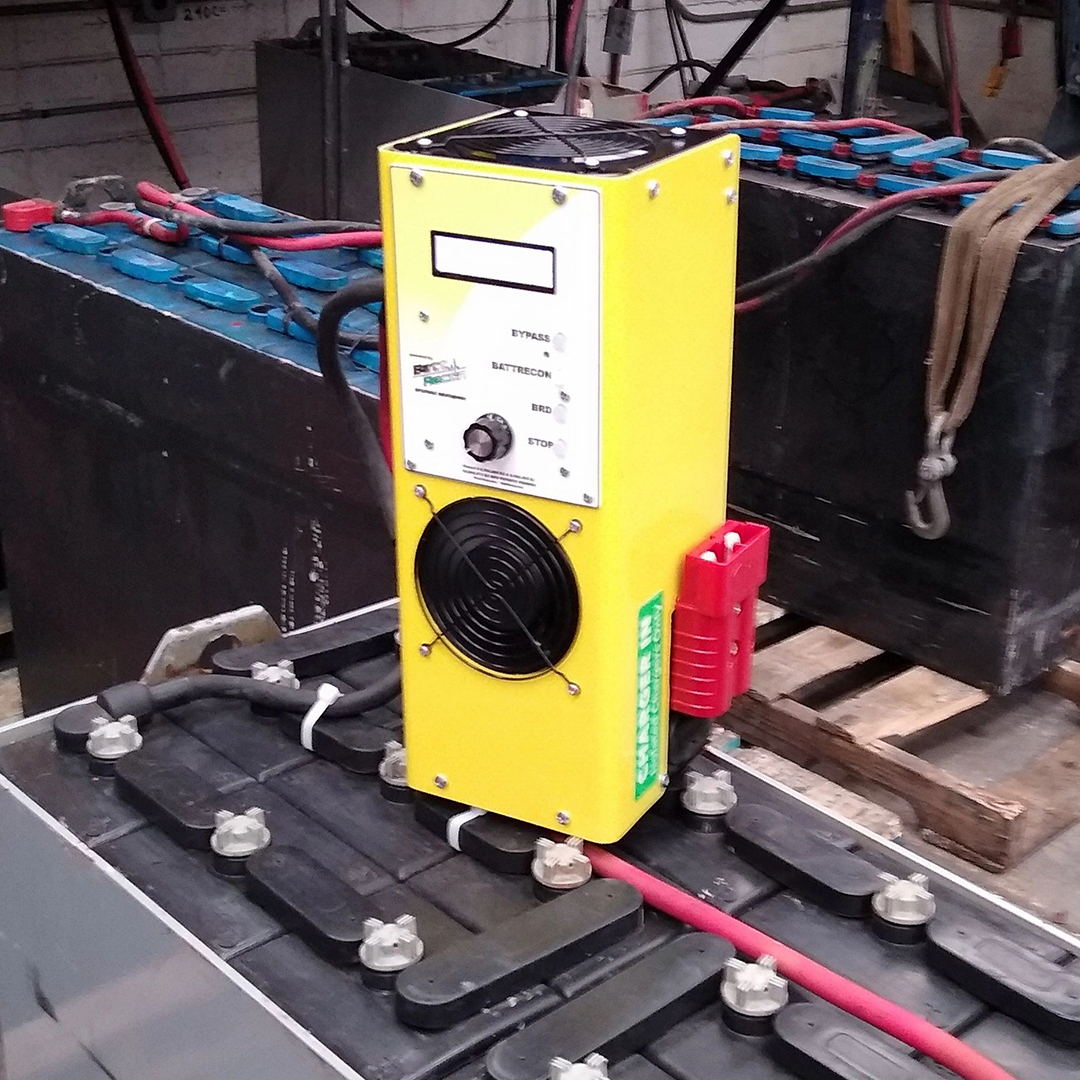

The BattRecon Model 8000 is portable, lightweight, and is powered from the battery itself; no external electrical connections are required. Our process is applied at the battery site, eliminating battery transportation, while silently operating in the background of a normal recharging operation.

Even forklift batteries that have lost performance from sulfation, or are in a low state of charge, may “self power” their way back to the fullest possible battery capacity with as little as one five-minute BattRecon treatment. While one desulfation treatment is considered minimum, one or two additional BattRecon desulfation and recharging cycles, such as during a Standard Optimization Cycle, provide the maximum benefit.

Cost-effective

This new process eliminates facility-based battery transportation and lost operator productivity, while also eliminating most technician labor/training and battery expertise requirements.

Reduce maintenance costs

Transporting the battery is expensive, disrupts the forklift operation and often requires a loaner or rental battery to keep the warehouse operational. Facility-based battery maintenance requires dedicated and trained personnel, vehicles, insurance, labor, and administrative costs, all of which are passed along to the end user of the battery as a battery servicing cost. None of these expenses actually improve the battery’s performance, they are just the marginal, sunk costs of facility-based desulfation. |

Extend your battery life

Battery preventive maintenance and restoration using the Model 8000, by contrast, eliminates most of those marginal costs, reduces battery watering frequency and typically extends the battery life expectancy several years. |

No service interruption = No productivity loss

BattRecon Model 8000 operates in the background during normal battery recharging. It may be permanently wired into a vehicle or base station, to automatically and periodically desulfate batteries. |

Low cost rental program available

Rent 1, 5, or up to 400 Model 8000 devices from us, when and as you need them.

Learn more

How does the 8000 work?

The Model 8000 replaces a technician’s skill and experience with our Patented BattRecon Artificial Intelligence Firmware Module.

The Model 8000 replaces a technician’s skill and experience with our Patented BattRecon Artificial Intelligence Firmware Module.

The BattRecon Artificial Intelligence Module

BattRecon A.I. initially conducts a battery diagnostic test to determine the battery’s condition, then applies varying pulse frequencies and amplitudes to determine the most efficient process to restore the battery’s maximum efficiency.

BattRecon A.I. continuously monitors and records the effect that each applied pulse has upon the battery, modifying subsequent pulses accordingly in real time to fully maximize battery performance.

At the completion of a BattRecon Desulfation Cycle, the A.I. displays a Qualitative Diagnostic Value of the battery’s performance on the Model 8000 control panel.

Subsequent applied BattRecon desulfation cycles may be compared to previous cycles, to formulate an estimated Qualitative Value of the performance restoration.

Use the Model 8000 as the standard Preliminary Diagnostic Tool

When your battery performance begins to slow, simply position the Model 8000 between your charger and the batteries to be recharged during normal operations. After only a few recharging cycles, if your battery is restored to serviceability, then you’re done! If not, then proceed to a facilities-based solution using the BattRecon Medic, our full diagnostic and restoration system.

Versions

The model 8000 has two variants.

80MV variant is for 24, 36 and 48 vdc automotive batteries from 100ah to 2000ah.

The 8012 variant is specifically for 12vdc automotive batteries.

Available versions:

| Cell tower service version |

| Mining battery version |

| Cargo ship battery version |

| Locomotive version |

| UPS and data center version |

During the previous 100 years of lead-acid battery operation, battery maintenance has been limited to charging and overcharging in an attempt to desulfate the battery, then performing external corrosion treatments and watering. There has never been a quick, effective way to desulfate a battery and restore lost performance without transportation to and from a dedicated, facility-based battery shop.

During the previous 100 years of lead-acid battery operation, battery maintenance has been limited to charging and overcharging in an attempt to desulfate the battery, then performing external corrosion treatments and watering. There has never been a quick, effective way to desulfate a battery and restore lost performance without transportation to and from a dedicated, facility-based battery shop. The Model 8000 replaces a technician’s skill and experience with our Patented BattRecon Artificial Intelligence Firmware Module.

The Model 8000 replaces a technician’s skill and experience with our Patented BattRecon Artificial Intelligence Firmware Module.